The conductive glass is SnO2 conductive glass doped with fluorine (SnO2: F), abbreviated as FTO, and its comprehensive performance is often evaluated directly by FTC: FTC=T10/RS. T is the transmittance of the film, RS is the square resistance of the film; in optical applications, it is required to have good transmittance to visible light and good reflectivity to infrared. Its basic requirements are: (1) low surface resistance, (2) high light transmittance, (3) large area and light weight, (4) easy processing and impact resistance.

SnO2 is a wide-bandgap oxide semiconductor transparent to visible light, with a forbidden band width of 3.7-4.0 eV and a regular tetrahedral rutile structure. After being doped with fluorine, SnO2 film has the advantages of good light transmittance to visible light, large ultraviolet absorption coefficient, low resistivity, stable chemical properties, and strong acid and alkali resistance at room temperature.

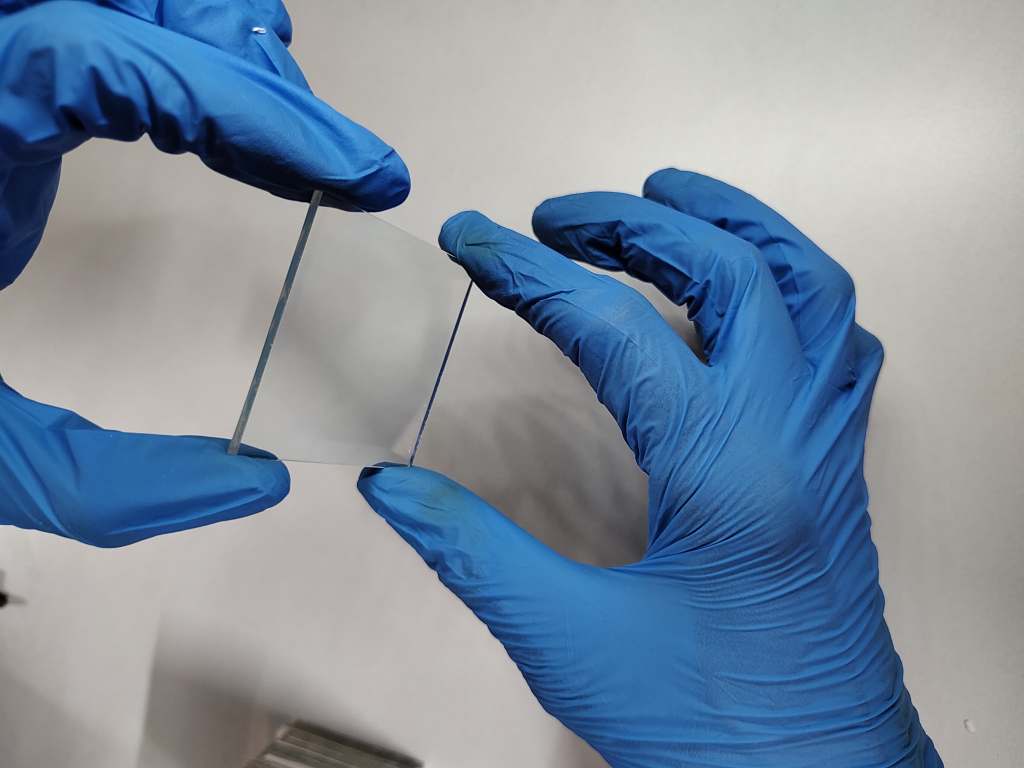

Conductive glass is fluorine-doped SnO2 conductive glass (SnO2:F), referred to as FTO. FTO glass can be used as a replacement for ITO conductive glass in many fields, used in liquid crystal displays, photocatalysis, electrochromic glass, thin film solar cell substrates, dye-sensitized solar cells, perovskite solar cells, etc. . Because of its large production size, high temperature resistance, and good environmental protection, it has become an irreplaceable transparent electrode material in the photovoltaic field.

Specifications of FTO coated glass substrate

- Surface resistance (SR): < 10 Ohm/sq

- Size: 25mm x 25mm / 50mm x 50mm // 100mm x 100mm

- Glass Thickness: 1.1 mm/ 2.2 mm

- Optical Transmittance > 83%

- Temperature ~600 Degree °C

- FTO Coating Thickness ~450 nm